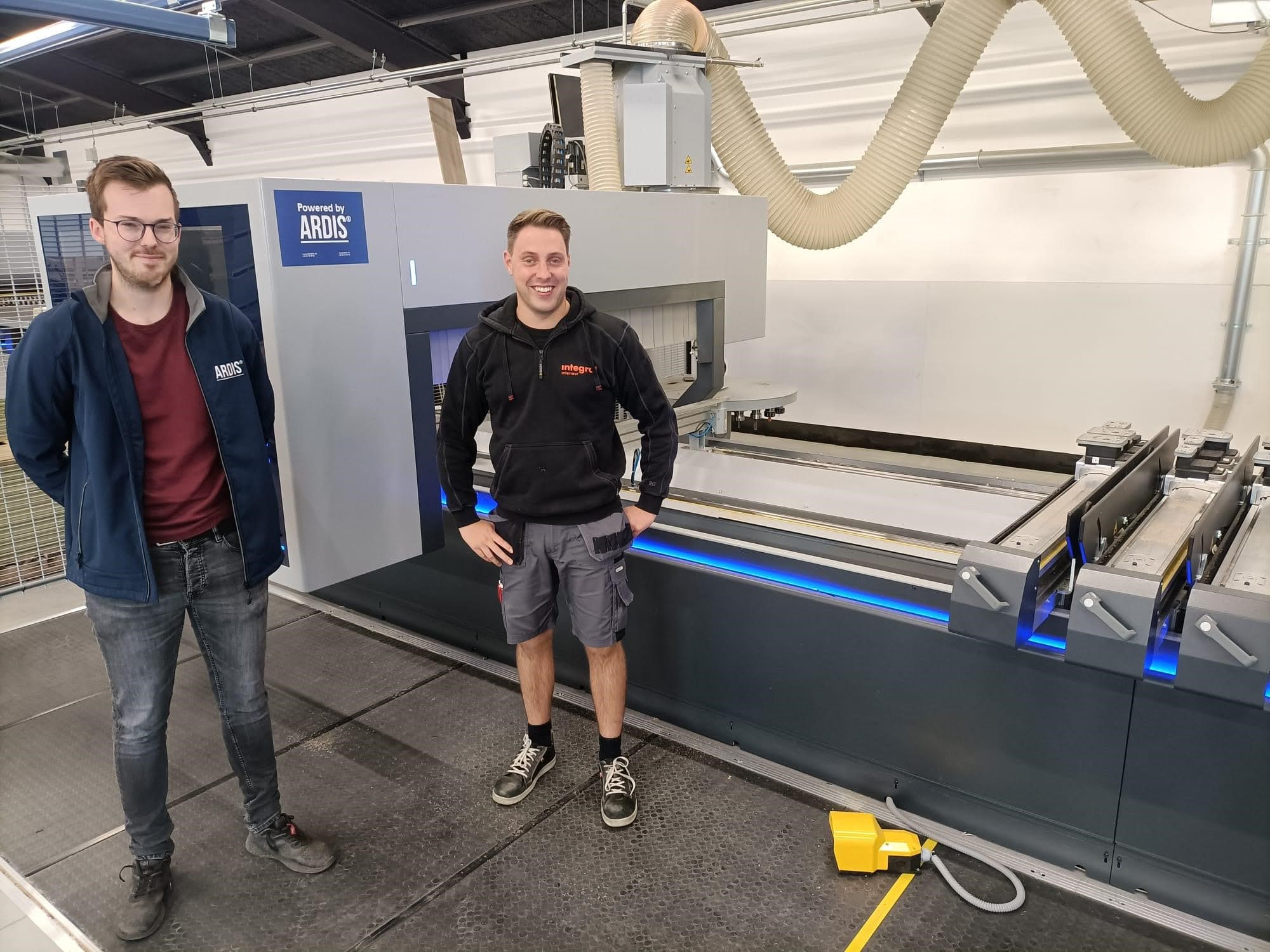

Integral

In the last couple of years Integral has invested heavily in order to increase the efficiency of their production process. By making active use of ARDIS® ANALYTICS, Integral was able to make the correct business decisions.

ARDIS® ANALYTICS gave Integral the right clues as to how they could move forward.

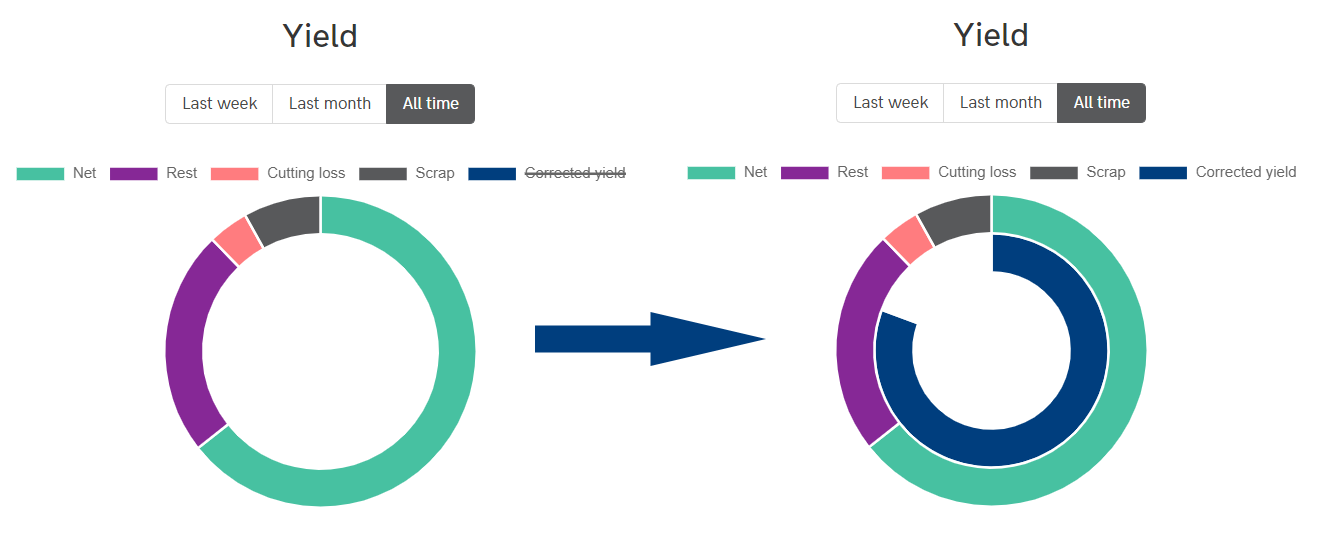

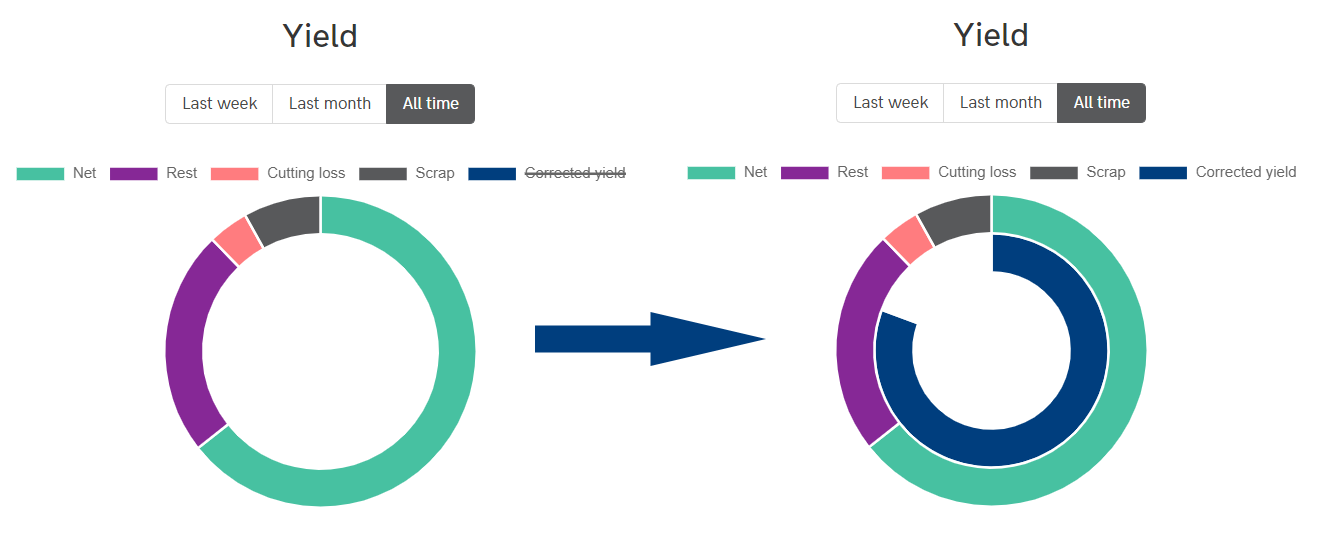

Indeed yield increase is obtained not only by making use of the best OPTIMZER, but also by actively managing offcuts. By keeping track of offcuts and reusing them in future optimization projects yield can be improved significantly.

Integral works with ARDIS® STOCK. This means that:

For Integral, it did not stop there. Recently, the following two ARDIS® solutions were implemented as well: